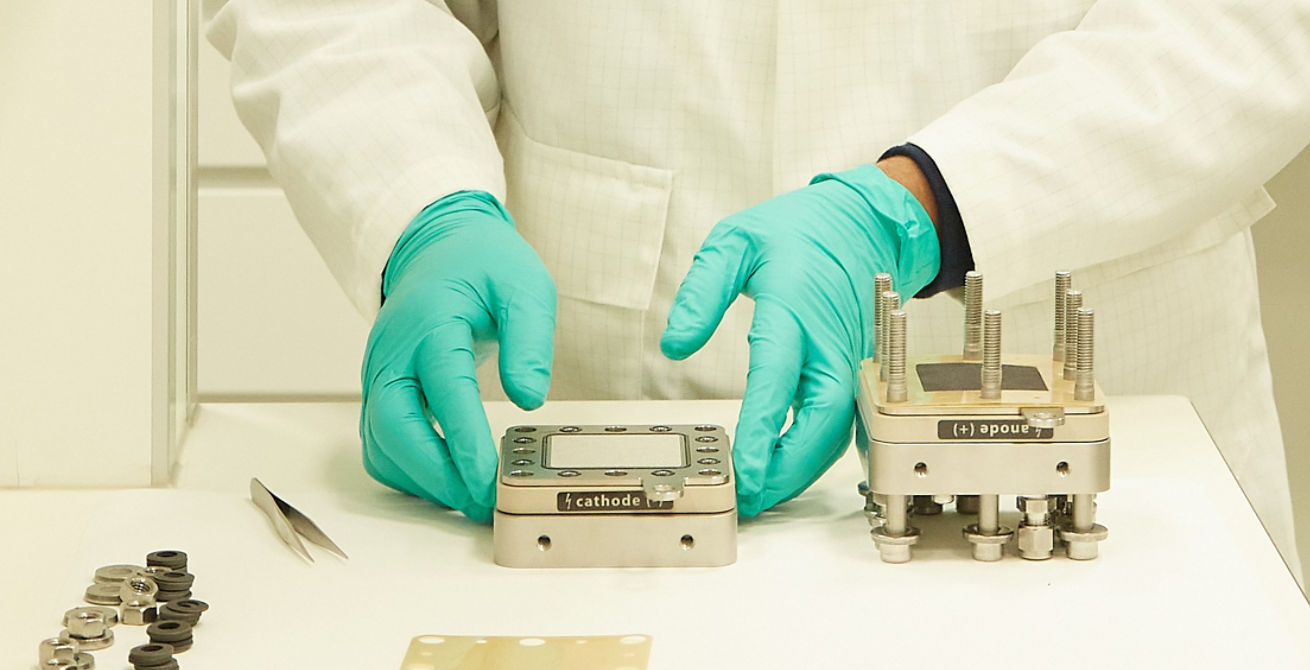

Among the various PTL materials begin developed, metal fibers stand as the frontrunner. They offer high performance and long-term stability that operating stacks require. Unlike flat sheet metals, or other types of PTLs, metal fiber PTLs feature a wide range of porosity without sacrificing strength. This means that they are able to provide optimal mass transfer at a wide range of current densities and withstand high pressures and repeated thermal cycling.

Material-wise, titanium PTL (plain or Pt coated titanium PTL) remains the gold standard for PEM electrolyzers. Although it comes at a higher cost, titanium's inherent corrosion resistance is ideal in acidic conditions. And, for AEM systems, nickel is the most common to offer a reliable solution in the strong alkaline media, while stainless steel provides a cost-effective solution in a milder environment.